Big current wiring Terminal is one of wiring terminals, by insulated base, and insulated clapboard, and line pieces composition, insulated base composition one, wiring pieces seat Yu insulated base Shang and placed insulated clapboard within, wiring pieces including wire clip, and screws, and nut and supports box, supports box is u shaped, wire clip placed supports box within, nut and screws along supports box u shaped ends surface of long shaped hole pressure live wire clip, wire clip by Shang wire clip and conductive tablets composition, Shang wire clip surface sides raised more row convex block, convex block Shang has a to II article convex reinforced, Its features is conductive tablets Shang surface sides raised more row convex block, convex block and Shang surface Central composition arc, arc surface Shang has a to II article convex reinforced, convex block and convex block formed sawtooth shaped, conductive tablets Shang surface middle for a raised platform, platform Central opened has thread hole and insulated base by bolt connected, conductive tablets Xia surface ends each raised a positioning round block and u shaped supports box connected, two block Shang wire clip respectively placed conductive tablets platform sides and and conductive tablets clip collection in together Shi, Wire clip and conductive film on bump (staggered occluding wire clamp.

Elinker Electric current electrical terminals:

1, UK series

2, UL-USLKG series

3, JHY1 series

4, TR series

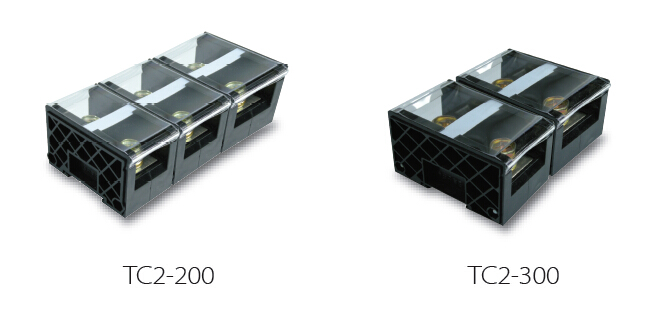

5, TC series

6, IN series

7、TA-150

Features:

Each area consists of an insulated, u-shaped bracket Hexagon screw, nut, and upper and lower blocks, between the upper and lower parts with connection holes, Hexagon socket screws with nuts on her block on, which are designed to vary the thickness of cable is connected directly on the current Terminal. Compared with the existing technology, which can be flexibly combined terminal splicing unit number, press-fit single or multiple cables and connections are secure, easy installation and maintenance and so on.

Material:

PA66 used materials do not contain halogens, combustion does not produce a corrosive acid vapor, in addition to PA66 with excellent ability to withstand adverse weather conditions, will not provide oxygen for microorganisms and other biological elements, so that it is made of pieces of insulation will not be due to the presence of anaerobic bacteria, fungi, termites, degrade its performance. PA66 to most oils and fats, alcohol, detergents such as carbon tetrachloride has an excellent resistance.

Manufacturing equipment.

Parts of insulating materials nylon PA66, with good electrical and mechanical properties. Resistivity (ω XMM): >1015; dielectric strength (KVxmm): 30; compared to tracking indices (CTI,V): 450; long operating temperature (¡æ): 100; minimum operating temperature (¡æ):-50. Provisions in accordance with UL94, flame retardant modified nylon PA66 grades from HB to V0.

Conductive:

Due to the metal part of a screw-type terminals mechanical strength requirements vary, constitute their alloys have varied and screws made from high-strength copper alloy, electric conductors made from electrolytic copper, wire frame stress crack corrosion-resistant copper alloy, which also Tin or nickel plating on the surface of the metal parts to be protected. All-copper wiring terminal block avoids steel metal fittings and copper wire in the battery under damp conditions effect. This corrosion can be avoided and their consequences – not a reliable electrical connection and the emergence of screws is rusty.

Current section:

1, the horizontal pressure line ensure that box to the base can also be clamped very fine wire, connection is safe and reliable.

2, a conductor can cut the wire perpendicular to the grain on oxide layer that may exist on, in order to achieve good resistance to pulling the connection.

3, line body structure, stability, and manufacturing tolerances allowed when small, Terminal contact pressure, thus guarantee gas-tight connection. Therefore, in corrosive environments ensure long-term stability of the connection.